For original construction, maintenance and repair of metal-clad buildings, the FAB-LOK® fastener is a unique combination of rivet and screw-combining the simplicity and strength features of both elements. FAB-LOK is a carbon steel or stainless screw assembled to a slotted "rivet" sleeve. The sleeve is 5052-H32 aluminum with a 1/2" OD neoprene sealing washer. A larger diameter WEATH-R-SEAL washer may also be used if the application requires greater bearing or a high-performance seal. Inserted through a 5/16" hole drilled in the sheeting members, the screw is tightened to cause the sleeve to draw up and form four clamping tines which provide the holding power.

FAB-LOK is recommended for use on metal-clad buildings wherever unusual conditions may cause conventional threaded fasteners to loosen and fall out.

Rollover Graphic on the right to see FAB-LOK during and after installation diagrams.

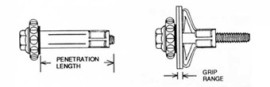

Sizing Information

Grip length is important. Determine the total thickness of materials to be fastened. Then add for job site conditions. Most often spaces occur between

the materials to be fastened and a longer grip length is necessary. A larger diameter sealing washer for roof applications also takes up some of the grip length.

| FAB-LOK Carbon Steel Screw, Aluminum Sleeve | ||||||||||||||||

| Carbon steel, cadmium plated #10-24 washer head machine screw, assembled to 5/8" 12-point head aluminum sleeve and neoprene sealing washer. | ||||||||||||||||

|

||||||||||||||||

| FAB-LOK Stainless Steel Screw, Aluminum Sleeve | ||||||||||||||||

| 18-18 Stainless steel, cadmium plated #10-24 hex washer head machine screw. Assembled to 5/8" 12-point head aluminum sleeve and neoprene sealing washer. |

||||||||||||||||

|

Adobe Acrobat document [299.0 KB]